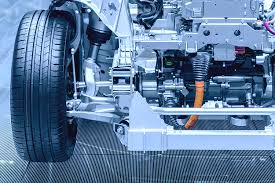

Rubber is a natural product which has to be processed in order to take any form. It is primarily used as an insulator in engines which are used for transport and other machinery which require a certain amount of energy. In fact, rubber can also be molded into the shape of almost any other object so that it can be added to almost any part of a machine or vehicle. This versatile material is what allows the rubber to be such a vital part of the motor industry, making it possible for rubber to be used in just about any automobile made today. If you need Rubber Mouldings, go to Meadex

From the definition above it should be clear that rubber is used throughout the motor industry as a means of making parts that are flexible enough to fit into certain machinery without the loss of overall efficiency. Because of this ability rubber has been used in conjunction with other materials such as plastics, making it possible to make motor parts which are both strong and durable. The most common parts made out of rubber in the motor industry include motors, pistons, seals, bearings, clutches, hoses, connecting rods.

There are two main types of rubber used in the motor industry. One type of rubber is polyisoprene rubber, which is often referred to as “plastic” rubber, as it possesses all of the same properties as plastic but is much stronger. Another type of rubber that is used in motor industry products is epoxy rubber, which is highly resistant to corrosion, has excellent heat resistance and is waterproof.